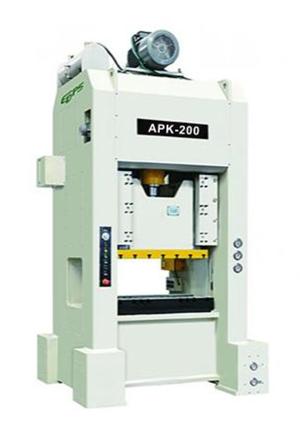

Product description

Straight side press features high precision, high stiffness, and high strength. And gap frame press features easy installation and operation. 125 Ton APK Series metal stamping press adopts welded steel plate in its frame, which possesses both the advantages of straight side press and gap frame press. Therefore, it is a cost effective product, which could be used in diverse machining processes, including cutting, punching, feeding, blanking, bending, and shallow drawing. Meanwhile, it is quite suitable for stator and rotor's stamping.

Product features

● Rotary encoder is adopted to control the different motions of press machine. Meanwhile, human machine interface system is also installed on the stamping press, which possesses intuitive active functions to perform, feedback on the results of those actions, and information on the system's performance.

● Threads of connecting rod are hydraulically locked, which helps to improve the precision of bottom dead center.

Parameters

| Name | Unit | APK-125 | |

| Nominal force | 125 TON [1250kn] | ||

| Rated tonnage point | mm | 3 | |

| Stroke | mm | 20 | 30 |

| Stable speed | s.p.m | 160-280 | 160-240 |

| Distance between the column | mm | 450x1160 | |

| Bolster area | mm | 1100x600 | |

| Slide area | mm | 1000x550 | |

| Material hole | mm | 880x150 | |

| Die height adjustment | mm | 350-400 | |

| Main motor | kw.p | 18.5 | |

Standard configuration

- Digital die height adjustment device

- 0.01mm Precision for die-0.01mm

- Inching device

- Batch control

- Misfeed detection device

- 0º and 90º positioning for multi-action press and single-action press

- Reversible device for press machine

- Hydraulic locking device for slide

- Free standing electrical cabinet

- Hydraulic die lifter

- Motor's variable-frequency drive

Optional configuration

- Bottom dead center sensor

- Rapid die lifter

- High speed feeder

- Double head hydraulic leveler

- Straightening and discharge machine

- Hydraulic anti-vibration mounts

- Automatic controller for stamping press