Of all the steel products, about sixty to seventy percent are of rectangular plate. After stamping, these rectangular plates could be manufactured as diverse products, including car body, chassis, fuel tank, radiator fin, boiler's steam drum, container shell, electric motor, silicon steel lamination for appliances and so on. Meanwhile, many stamping parts are also installed on instruments of equipment, household appliance (telephone, television, computer), bicycle, office machinery and etc.

- Yiduan's stamping press features stable performance, safe operation, high precision and energy saving. They could well meet diverse machining requirements from customers, such as installing stiffening ribs, ridges, and flanging on metal parts. These designs allow for a higher stiffness.

- Stamping parts manufactured with Yiduan's stamping press feature thin in thickness, even in surface, light in weight, and high in stiffness. Meanwhile, when machined with precision stamping press, stamping parts only allow a micro-grade tolerance, and they possess high uniformity in precision and standard. Besides that, with our precision stamping press, we could even manufacture shield boss and other fine parts.

Yiduan's press machine has been widely used in sheet metal's cutting, forming and deep drawing. It could also be equipped with an automatic feeding machine, which allows for an automatic transferring in the production line. Meanwhile, with the technology's development, products' performance is becoming more and more stable.

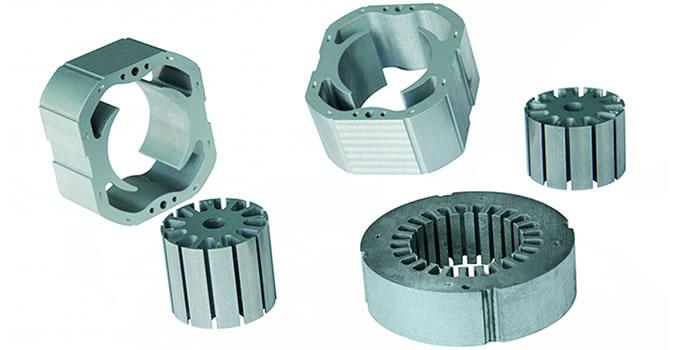

Yiduan possesses cooperative relationship with many automobile manufacturers, including Mazda, Nissan, and Volkswagen. Meanwhile, our products are also well used in electric motor manufacturing industry. Therefore, Yiduan has built a tight cooperation with Broad-Ocean Motor, and all the stamping presses in the production line are all from Yiduan.