Product description

APD series 200-ton precision metal stamping press has a high precision of 0.1mm, and it features easy operation and reliable performance. Meanwhile, it adopts semi-closed structure, which contributes to high stamping stability. Meanwhile, semi-closed structure also helps to prevent C-shape opening and low stamping precision caused by long-period stamping. Therefore, the stamping press is widely used in diverse parts' stamping and forming, such as electronic tools, communication tools, computer parts, home appliance parts, vehicle components (automobiles, motorcycles and bicycles), hardware tools and etc.

Product features

● High stiffness for its frame: Quality welded steel plates are adopted as the raw material of 200 - ton stamping press's frame. These plates undergo stress relieving, which allows for a high and stable presses precision.

● Precision stamping press possesses same center with its driving center, which allows for a stable and precise stamping.

● Two balancing devices are installed on our 200 Ton precision stamping press, which allows a relatively stable operation.

● Allowable tolerance for this press machine is 0.1mm, which enables safe, convenient and reliable operation.

● After hard anodizing, grinding and other machining, our crankshaft, gears, connecting rods and other components all possess high performance in its physical and chemical properties.

● Since 200-ton precision metal stamping press is equipped with clutch, brake, double solenoid valve (controlling clutch by cutting off or putting through the air supply), overload protector, the safe and precise operation of stamping press's slides is guaranteed.

Parameters

| Name | Unit | APD-200 | |

| Model | V | H | |

| Capacity | Ton | 200 | |

| Rated tonnage point | mm | 6 | 3 |

| Stroke | mm | 200 | 100 |

| Die height | mm | 460 | 510 |

| Stroke per minute | s.p.m | 20-50 | 50-70 |

| Slide adjustment | mm | 110 | |

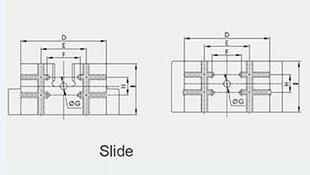

| Slide area | mm | 850X630X90 | |

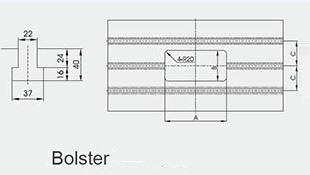

| Bolster area | mm | 1140x820x160 | |

| Main motor | kwxp | 18x4 | |

| Slide adjust device | HP | Electrical driving | |

| Air pressure | kg/cm2 | 6 | |

| Presses dimension | mm | 1750x2500x3900 | |

| Presses weight | Ton | 25.3 | |

| Presses precision | GB(JIS) class1 | ||

| Die cushion capacity | Ton | 14 | |

| Stroke | mm | 100 | |

| Die cushion effective area | mm2 | 710X480 | |

Overall dimension

| MODEL | A | B | C | D | E | F | G | H | 1 |

| APD-200 | 480 | 240 | 280 | 850 | 420 | 200 | 065 | 220 | 630 |

Standard configuration

- Transducer

- Hydraulic overload protection system

- Digital slide adjustment device

- Mechanical die height indicator

- Slides and die counterbalancing device

- Misfeed detector

- Power socket

- Rotary cam switch

- Crankshaft position sensor

- Counter

- Air supply connector

- Die over-run protection device

- Maintenance tools and tool kit

- Operation manual

Optional configuration

- Automatic grease lubrication system

- Hydraulic die cushion

- Preset counter

- Precut counter

- Foot switch

- Rapid die change device (die lifter, die clamp, mold shift arm)

- Upper slide feeding device

- Press anti-vibration mounts

- Light curtain safety device

- Feeder (air feed, mechanical feeder, NC servo feeder)

- Die rack

- Straightening machine

- Robotic arm

- Lighting device for dies

- Left (right) feeder

- PAC 100 programmable automation controller

- Man-machine system