Product description

25 Ton API series stamping press can be used to process small electronic components with high precision and large yield, such as communication components, computer components, small components of household appliances, stator, rotor and other small components.

Product features

● High-strength cast, long-term precision can be ensured after eliminating stress

● The punch machine uses alloy steel bushing with forced lubrication, minimizing the thermal changes of slider and maximizing precision.

● The punch machine uses dynamic balance system to balance the tremor caused by high-speed crank and slider, making the machine steadier.

● We can adjust die height manually. And the punch machine is equipped with die height indicator and hydraulic clamping device.

● Human machine interaction (electronic cam and rotary encoder) makes operation convenient and precise.

● Integrated LCD screen contains all kinds of operation functions and it can automatically display the fault of base.

● Clutch / brake device with high sensitivity and international advanced single solenoid valve can ensure the safety and precision of slider.

● Electrical circuit of interior electrical appliances is reasonable. And the punch machine can automatically produce product with all kinds of automatic equipment, reducing costs and improving efficiency.

Parameters

| Name | unit | API-25 | |

| Model | A | B | |

| Capacity | ton | 25 | |

| Stroke | mm | 30 | |

| Stroke per minute | s.p.m | 200-600 | 200-800 |

| Die height | mm | 210 | |

| Bolster | mm | 600x300x80 | |

| Area of slide | mm | 300x205 | |

| Slide adjustment | mm | 30 | |

| Bed opening | mm | 200x100 | |

| Motor | Kw | 3.7 | |

| Weight | kg | 3000 | |

| Lubrication | Forceful Automation | ||

| Speed control | Inverter | ||

| Clutch & brake | Air & Friction | ||

| Auto top stop | Standard | ||

| Vibration system | Optional | ||

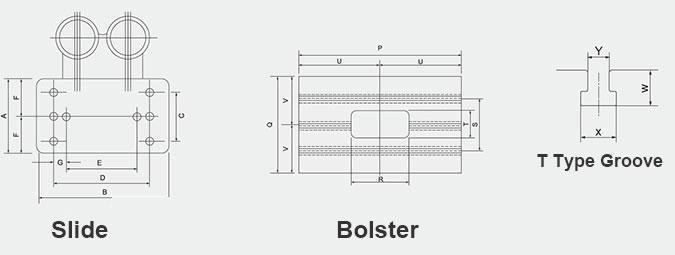

Dimensions

| Model | A | B | c | D | E | F | G | P | Q | R | S | T | U | V | W | X | Y |

| API-25 | 205 | 300 | 150 | 212 | 190 | 102.5 | 25 | 600 | 300 | 200 | 180 | 100 | 300 | 150 | 30 | 30 | 18 |

Standard configuration

- Top stop

- Manual slide adjusting device

- Programmable logic controller

- Touch screen (preset, angel indicator, counter)

- Electronic encoder: 2 sets

- Operation cabinet at the front of frame

- Air supply connector

- Sticking release device

- Main motor (adjustable)

- Hydraulic clamping device

- Mechanical angle indicator for crank

- Forced circular lubrication device

- Tool kit

- User manual

- Power socket

- Free standing electrical cabinet

Optional configuration

- Press anti-vibration mounts

- Feeder

- Die rack

- Lubrication device

- Bottom dead center sensor

- Oil cooling machine

- Lighting device for dies

- Air blasting device